How can you get a handle on your performance measures and which measures are indicating what?

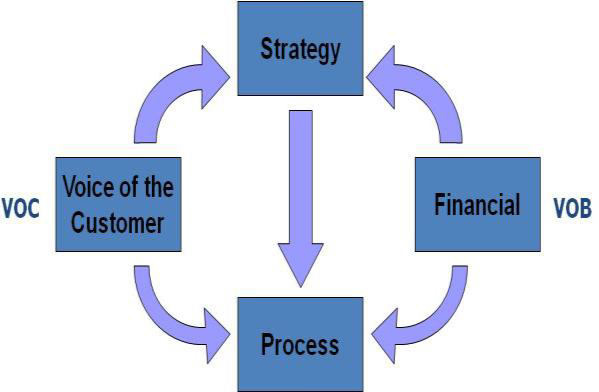

Organizational effectiveness hinges on ensuring you’re putting enough resources on the right business processes (the key work processes that your organization pursues that create value for your customer). Additionally, how well you perform those processes forms the essence of how efficient your organization is at producing value to the customer. But what are all the key support processes? And how much resource is required to run those critical support processes? How do you even start to differentiate between your key support processes, and your key business processes?

So as a senior leader you’re monitoring a lot of performance measures, but which measures are key? And which measures are predictors of major business trends or in process measures? What should you be looking at to provide a check on major business performance and allow enough time to adjust resources to ensure sustained results?

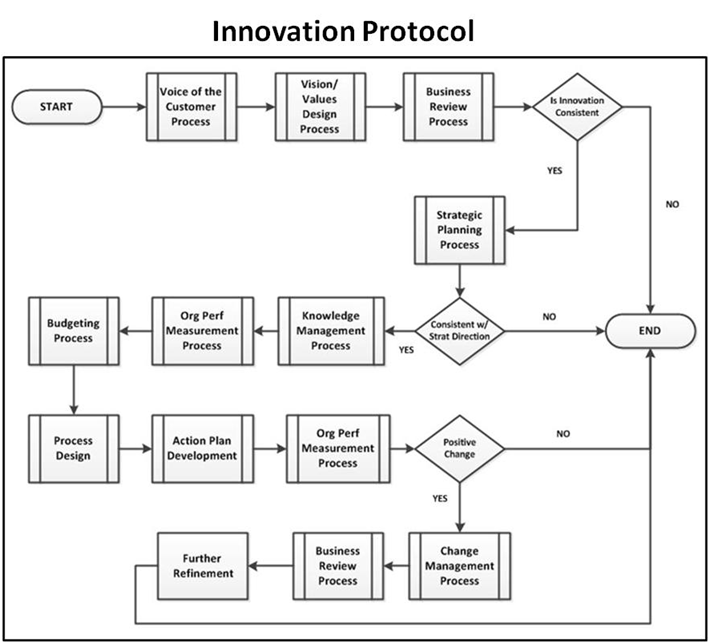

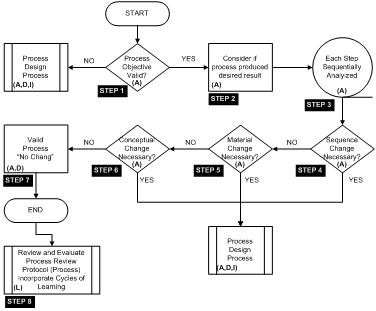

Or, is there no process in place at all, and are decisions and the analysis that supports those decisions ad-hoc? Is there a decision “science” to analyze problems and a systematic method to uncover root cause(s) to problems? Do politics and intuition have a disproportionate impact on driving your decisions? Or do you use valid data to support your business decisions?

Having a sound method of determining your key business processes and key supporting processes is a good place to start in differentiating between the myriad of performance measure you’re monitoring.

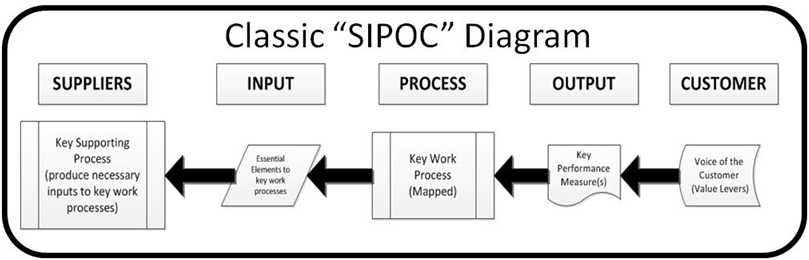

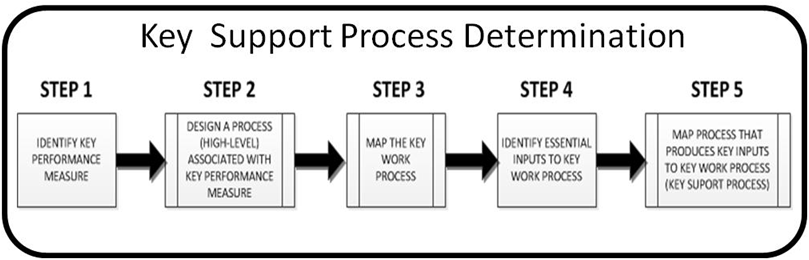

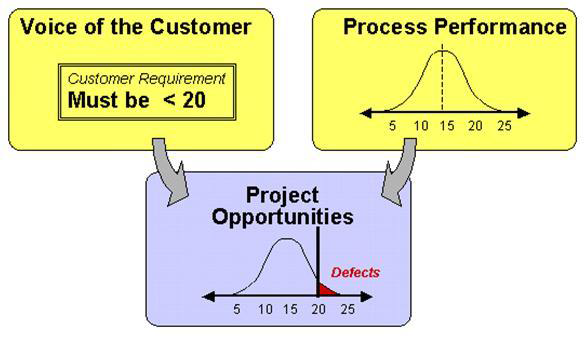

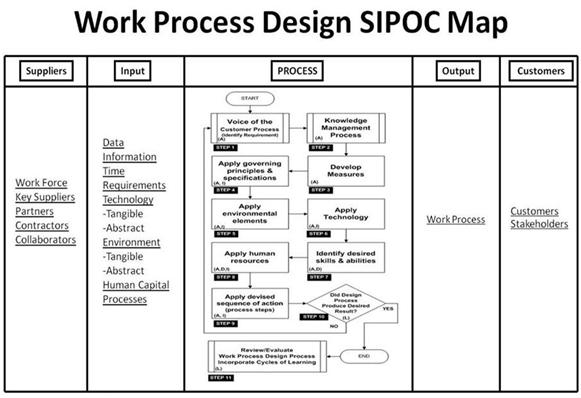

As a rule of thumb, key support processes produce key work process inputs (business support requirements). Key business support requirements are fundamental, essential, crucial, or indispensable process inputs needed for successfully producing a key work process output. Your key performance measures are most closely associated with the voice of your customer and key value levers (key business processes). You work backward from voice of your customer through your key performance measures.

It is essential to identify those required/essential inputs to your key work processes. These by definition are your key support process. Now move to a more refined mapping process to capture your key support processes and the performance measures associated with them.

Your key performance indicators are now better defined along with those key “in process” indicators; namely your key support process measures which enable a more proactive approach to managing your business processes. Your decisions to allocate the necessary resources can now be more deliberate and backed up by data versus intuition.